STATION PICKING

In order to accelerate order picking and reduce the error rate, we use our hardware and software components individually to suit your strategy. The station principle, for example, is always useful when fast-moving items are to be processed with an extreme throughput.

With the station principle, each “station” (workstation) is equipped with our pick2light hardware. With our ix.tech software, individual “stations” can be defined and conveniently structured and expanded via the configuration.

How does it work?

There are several stations in a picking area.

The order is transported from station to station. In each area, the respective employee gets the work steps visualised by pick2light modules at the respective picking compartments and, if applicable, a terminal. The ix.tech software communicates with your ERP or warehouse management system and maps the process with the help of the attached hardware.

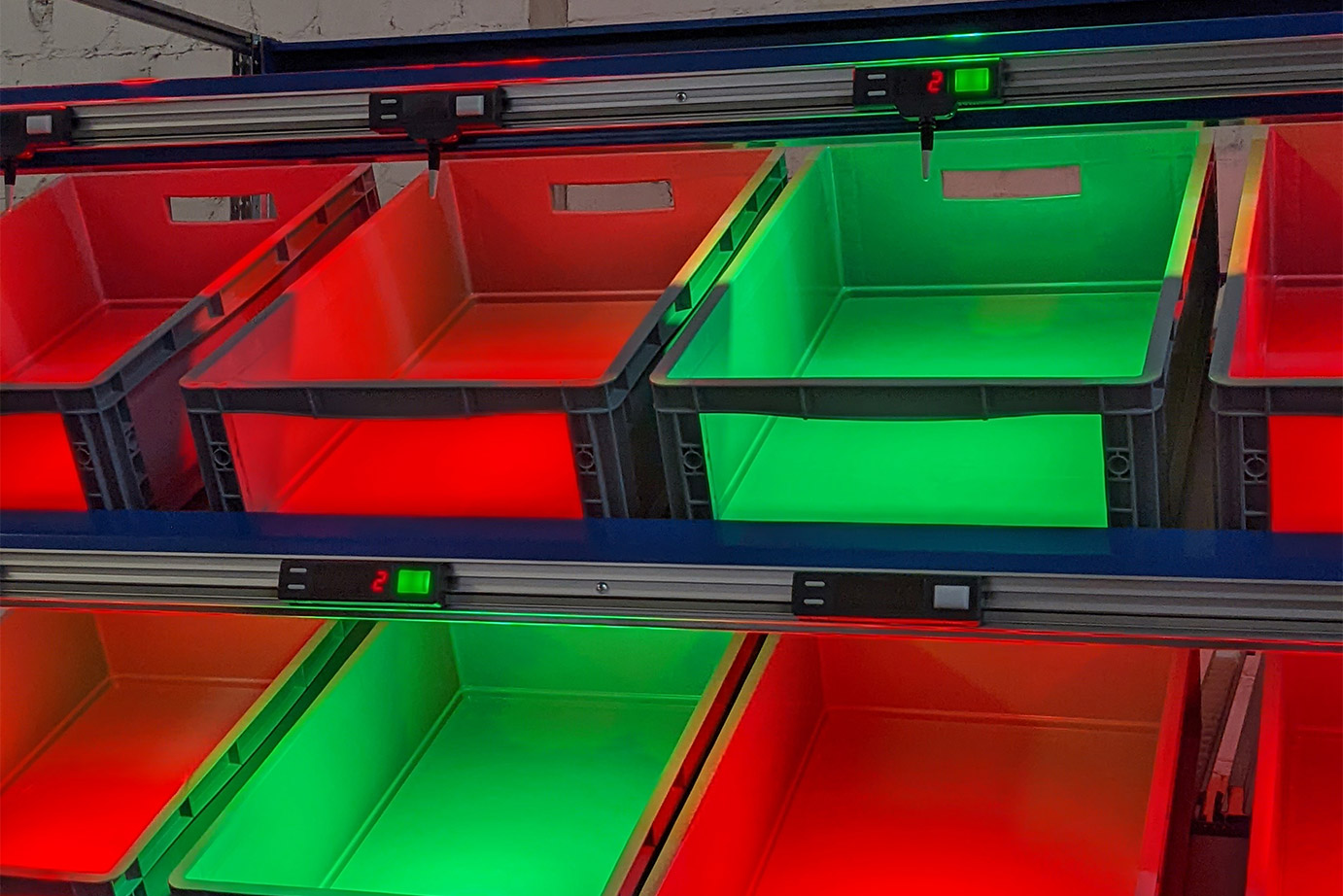

In station picking it is particularly important to be able to clearly identify each order. The change of colour depending on the order also enables your employees to work safely and easily follow the sequence.

The respective order picker is always close to the pick point, so that long travel times are eliminated. Due to the significantly reduced travel times, the picking performance can be increased many times over.

Buffer storage can be set up between the individual zones to compensate for different picking times in the individual zones. In this way, several orders can be worked on in parallel and long waiting times can be avoided. The ix.tech software allows you to work very dynamically. This means that the zone configurator allows you to design the number and size of the individual stations as you wish. With the help of the zone dependency, the individual zones are informed about the current status of the other zones at any time. It is also possible to switch easily between different modes, such as batch mode and special customer mode.

The ix.tech software and hardware components enable you to optimise your order picking strategy in order to reduce the error and thus also the return rate and to increase the efficiency of the employees.

GUIDE THROUGH WORK STEPS

VISUALISATION OF PICKING TRAYS

CLEAR IDENTIFICATION OF ORDERS

Advantages Production line

FLEXIBILITY

+ Any connection of hardware components such as scanner, terminal, intervention control, etc.

+ Easy change to different modes

+ Zones can be scaled as desired

SORTING IS NOT NECESSARY

+ Items no longer need to be re-sorted to orders

BETTER TIME MANAGEMENT

+ Long walking times are eliminated, picking performance can be increased many times over

+ Buffer storage can be set up to compensate for picking times