Our Process:

- Listen, understand, and develop the recommended solution

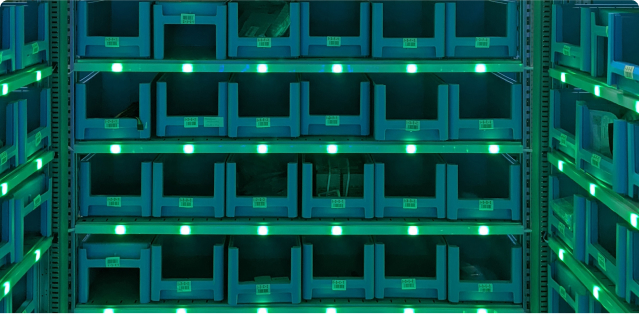

- Optimization of walking paths through U-shaped shelf arrangement

- Installation of the Pick-by-Light hardware

A total of 5,600 storage locations and several picking carts were equipped with our pick2light modules. In combination with the ix.mate handheld devices and the customized pack2light solution, a fully compatible warehouse process optimization was implemented for anzado.